In the automotive industry, Repair Quality Verification (RQV) is essential for maintaining OEM (Original Equipment Manufacturer) compliance in vehicle repairs, especially collision and frame straightening. RQV ensures that all repairs meet stringent OEM standards by employing advanced technology and precise workflows, thereby enhancing consumer safety and protecting brand integrity while fostering excellence within the auto repair sector.

In the stringent world of Original Equipment Manufacturer (OEM) compliance, ensuring every part meets high-quality standards is paramount. This is where Repair Quality Verification (RQV) steps in as a game-changer. RQV plays a pivotal role in validating repairs, preventing fraudulent claims, and maintaining OEM integrity. By employing rigorous testing and inspection, it safeguards consumers and brands alike, fostering trust in the supply chain. This article delves into the significance of RQV, exploring its impact on compliance and offering best practices for effective implementation.

- Understanding OEM Compliance and Its Impact

- The Role of Repair Quality Verification in Ensuring Adherence

- Benefits and Best Practices for Effective Implementation

Understanding OEM Compliance and Its Impact

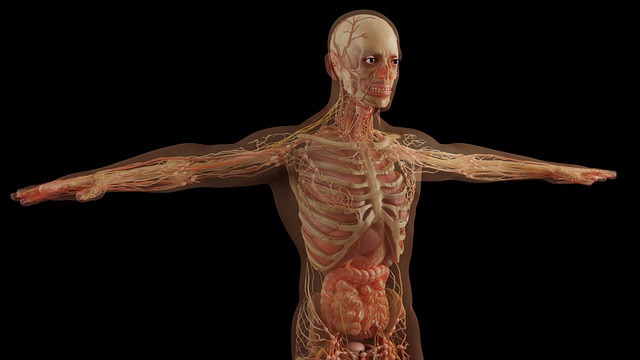

OEM (Original Equipment Manufacturer) compliance is a critical aspect of ensuring that products meet specific quality and safety standards set by the original manufacturer. In the automotive industry, this means adhering to strict guidelines for every component, from engine parts to exterior panels like those involved in car collision repair. Non-compliance can lead to legal issues, damage to brand reputation, and even safety hazards.

Repairs, especially in auto body work such as auto body painting, must accurately reflect the original manufacturer’s specifications. Repair quality verification plays a pivotal role here by ensuring that every repaired or replaced part meets OEM standards. This meticulous process verifies the authenticity, functionality, and aesthetic integrity of components, thereby safeguarding both consumer safety and brand integrity.

The Role of Repair Quality Verification in Ensuring Adherence

Repair Quality Verification (RQV) plays a pivotal role in ensuring Original Equipment Manufacturer (OEM) compliance for vehicle repairs, particularly in the realms of auto collision repair and frame straightening. It acts as a quality control measure that verifies the precision and integrity of the repair process, guaranteeing that vehicles meet the stringent standards set by their original equipment manufacturers.

By implementing rigorous RQV protocols, repair facilities can confirm that every step of the repair process, from initial assessment to final inspection, aligns with OEM specifications. This is especially critical in the complex world of car collision repair, where precision and accuracy are paramount. Any deviation from the prescribed standards could lead to potential safety risks and compromise the structural integrity of the vehicle. RQV ensures that these risks are mitigated, fostering a culture of excellence and adherence to OEM guidelines within the auto repair industry.

Benefits and Best Practices for Effective Implementation

Implementing a robust repair quality verification (RQV) process is not just beneficial; it’s essential for achieving Original Equipment Manufacturer (OEM) compliance in automotive repair, especially when addressing issues like vehicle dent repair or car damage repair. RQV ensures that every repair, including collision collision repair services, meets the stringent standards set by vehicle manufacturers. This verification step acts as a quality control measure, catching potential errors or inconsistencies early on and preventing subpar work from being approved.

Best practices for effective repair quality verification involve integrating it seamlessly into the repair workflow. This includes utilizing advanced technology like digital measurement tools and image comparison software to document repairs accurately. Collaboration between technicians, inspectors, and OEMs is crucial, fostering an environment where knowledge sharing enhances overall repair standards. Regular training sessions on RQV procedures and industry updates ensure that all stakeholders remain aligned with the latest best practices, further strengthening compliance efforts in car damage repair and vehicle dent repair.

Repair Quality Verification (RQV) is a vital process for Original Equipment Manufacturers (OEMs) to maintain compliance and ensure product integrity. By implementing rigorous RQV protocols, OEMs can guarantee that repairs meet or exceed the original equipment standards, thus preserving product quality, safety, and reliability. This strategic approach not only satisfies regulatory requirements but also enhances customer satisfaction by fostering trust in the after-sales service process. Adopting best practices for RQV enables OEMs to streamline their operations, reduce costs, and maintain a competitive edge in the market.